Now Reading: Understanding Casting Heat: A Comprehensive Guide

-

01

Understanding Casting Heat: A Comprehensive Guide

Understanding Casting Heat: A Comprehensive Guide

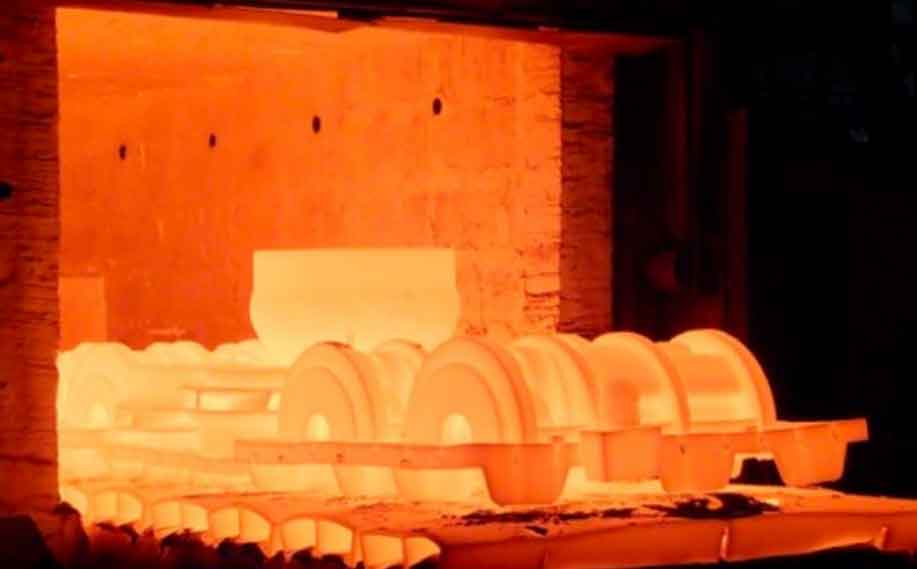

Welcome to the fascinating world of metal casting! It’s a process that has shaped human civilization for thousands of years, giving us everything from simple tools to complex engine components. At the very core of this transformative process is the concept of casting heat. Without a deep understanding of how to manage and apply heat, turning solid metal into a liquid and then into a finished product would be impossible.

This guide will walk you through everything you need to know about casting heat. We will explore what it is, why it’s so critical, the different stages involved, and the various technologies used to control it. Whether you are a student, a hobbyist with a backyard furnace, or an industry professional, this article will shed light on the thermal dynamics that make metal casting work. We will cover the science, the safety, and the practical applications of heat in this essential manufacturing process.

Key Takeaways

- Casting heat is the thermal energy required to melt metal and manage its temperature throughout the casting process.

- Precise temperature control is crucial for metal quality, mold integrity, and the final properties of the cast part.

- The process involves several stages: preheating, melting, superheating, pouring, and controlled cooling.

- Different metals have vastly different melting points and thermal characteristics, requiring specific approaches.

- Safety is paramount when dealing with the extreme temperatures involved in casting.

What Exactly is Casting Heat?

At its most basic level, casting heat refers to the thermal energy applied to a solid material, typically metal, to raise its temperature past its melting point and transform it into a liquid state. This molten material can then be poured into a mold to create a desired shape. However, the term encompasses more than just melting. It includes the entire thermal management of the process, from the initial heating of the raw material to the controlled cooling of the final cast object.

Effective management of casting heat is a science and an art. It involves knowing the exact temperatures needed for different alloys, how long to hold the metal at that temperature, and how to pour it without losing too much heat. It also includes understanding how the heat will interact with the mold material. Too much heat can damage the mold, while too little can result in a failed casting. Therefore, casting heat is the single most important variable that casters must control to achieve consistent, high-quality results.

The Critical Role of Temperature in Metal Casting

Temperature isn’t just a number on a gauge; it’s the controlling factor that dictates the success or failure of a casting project. Every step of the process is sensitive to temperature, and getting it wrong can lead to a host of problems, from cosmetic blemishes to complete structural failure. The precise application of casting heat ensures that the metal flows properly, fills the mold completely, and solidifies in a way that produces a strong, durable part.

For instance, if the molten metal is not hot enough, it may begin to solidify before it has filled all the intricate details of the mold. This results in an incomplete part, known as a misrun. On the other hand, if the metal is too hot, it can react with the mold material, causing defects on the surface of the casting. Overheating can also burn away valuable alloying elements, changing the metal’s properties, or introduce unwanted gases into the liquid metal, leading to porosity. This is why foundries invest heavily in accurate temperature measurement tools and sophisticated furnace controls to manage casting heat effectively.

Impact on Metal Fluidity

Fluidity is a term used to describe how well molten metal flows. It is directly influenced by the amount of casting heat applied beyond the metal’s melting point. This extra heat is called superheat. Higher superheat generally leads to better fluidity, allowing the metal to travel further and fill thinner sections of a mold. However, there’s a delicate balance. Excessive superheat can cause the issues mentioned earlier, such as mold-metal reactions and gas porosity. Different metals have different fluidity characteristics, and experienced casters know just how much superheat to apply to achieve a perfect pour without introducing defects.

Controlling Microstructure and Mechanical Properties

The final properties of a cast part—its strength, hardness, and ductility—are determined by its internal grain structure, or microstructure. This structure is formed as the metal cools and solidifies. The rate of cooling, which is managed as part of the overall casting heat process, plays a crucial role. Rapid cooling generally produces a fine-grained structure, which is often harder and stronger. Slower cooling results in a coarser grain structure, which is typically more ductile. By carefully controlling the cooling rate after the pour, manufacturers can tailor the mechanical properties of the part to meet specific engineering requirements.

The Stages of Applying Casting Heat

The application of casting heat is not a single event but a carefully orchestrated sequence of stages. Each stage has a specific purpose and requires precise temperature control to ensure a successful outcome.

Stage 1: Preheating the Crucible and Tools

Before any metal even enters the furnace, the first step is often to preheat the equipment. This includes the crucible (the ceramic or metal pot that holds the molten charge) and any tools that will come into contact with the molten metal, such as ladles and stirrers. Preheating serves two main purposes. First, it drives off any moisture absorbed by the refractory materials. Introducing damp tools or a damp crucible to molten metal can cause a dangerous steam explosion. Second, it reduces thermal shock. Pouring hot metal into a cold vessel can cause it to crack. Bringing the equipment up to temperature slowly prevents this and helps maintain the temperature of the molten metal during transfer.

Stage 2: Melting the Metal

This is the most energy-intensive stage of the casting heat process. Solid metal, known as the charge, is loaded into the crucible and heated until it reaches its specific melting point. The amount of heat required depends on the type of metal, its mass, and its starting temperature. During this phase, it’s important to monitor the process to ensure even melting. Sometimes, a “heel” of molten metal from a previous batch is left in the crucible to help speed up the melting of the new charge. Fluxes are often added at this stage to help remove impurities, which float to the surface as slag and can be skimmed off.

Stage 3: Superheating and Holding

Once the metal is fully molten, it is not yet ready to be poured. Additional casting heat is applied to raise its temperature above the melting point. This is the superheating stage. As discussed, superheat is vital for ensuring the metal has enough fluidity to fill the mold cavity completely. The target temperature for superheating varies significantly depending on the alloy and the complexity of the part being cast. After reaching the target superheat temperature, the metal may be held at that temperature for a short period. This allows for any final treatments, such as degassing or adding alloying elements, and ensures the temperature is stable and uniform throughout the entire batch of molten metal.

Stage 4: Pouring and Solidification

The pouring stage is where the carefully managed casting heat is put to the test. The molten metal is transferred from the furnace to the mold. The goal is to perform this transfer quickly and smoothly to minimize heat loss and turbulence. The temperature of the metal as it enters the mold is known as the pouring temperature. As the metal fills the mold, it begins to lose heat to the surrounding mold material. This initiates the final stage: solidification. The cooling rate during solidification is critical for the final grain structure and is influenced by the mold material, the part’s thickness, and sometimes external cooling methods.

Common Furnace Technologies for Casting Heat

The furnace is the heart of any casting operation, responsible for generating and controlling the immense casting heat required. There are several types of furnaces used in the industry, each with its own advantages and best-use cases.

Induction Furnaces

Induction furnaces are one of the most popular choices in modern foundries. They use electromagnetic induction to generate heat directly within the metal charge itself. A powerful alternating current is passed through a coil that surrounds the crucible. This creates a strong magnetic field, which in turn induces eddy currents within the metal. The metal’s natural electrical resistance causes it to heat up rapidly and melt. Induction furnaces are known for their speed, energy efficiency, and clean melting process, as there is no direct contact between the heating element and the metal. They also provide a natural stirring action, which helps create a homogeneous molten bath.

Electric Resistance Furnaces

Electric resistance furnaces are conceptually simpler. They work much like a conventional electric oven, using heating elements made from a high-resistance material. When electricity passes through these elements, they heat up and radiate thermal energy, which then heats the crucible and melts the charge. While they are generally less expensive to purchase than induction furnaces, they are often less energy-efficient and slower to melt. They are commonly used for holding molten metal at a specific temperature and for melting lower-temperature non-ferrous alloys like aluminum and zinc.

Gas-Fired Furnaces

Gas-fired furnaces burn a fuel source, such as natural gas or propane, to generate casting heat. A burner directs a flame into the furnace chamber, heating the crucible and its contents through convection and radiation. These furnaces are robust, relatively inexpensive to operate, and can reach very high temperatures, making them suitable for a wide range of metals, including brass, bronze, and even iron. However, they can introduce combustion byproducts into the melt if not properly managed, and they are generally less precise in temperature control compared to electric furnaces. They are a popular choice for hobbyists and smaller foundries.

|

Furnace Type |

Heating Method |

Key Advantages |

Common Applications |

|---|---|---|---|

|

Induction Furnace |

Electromagnetic Induction |

Fast, clean, energy-efficient, stirring action |

High-quality steel, iron, copper alloys |

|

Resistance Furnace |

Electrical Resistance Elements |

Lower initial cost, good for holding |

Aluminum, zinc, magnesium |

|

Gas-Fired Furnace |

Fuel Combustion (Gas/Propane) |

Robust, lower operating cost for some fuels |

Hobbyists, small foundries, brass, bronze |

Casting Heat for Different Metals

Not all metals are created equal when it comes to their thermal requirements. The type of metal being cast is the primary factor determining the parameters for casting heat. Everything from the melting temperature to the ideal pouring temperature is specific to each alloy.

Ferrous Metals: Iron and Steel

Ferrous metals, those based on iron, have very high melting points. Cast iron, for example, melts at around 2,200°F (1,200°C), while steel requires even higher temperatures, often exceeding 2,800°F (1,540°C). Generating and containing this level of casting heat requires robust furnaces, typically induction or arc furnaces, and specialized refractory materials that can withstand the extreme temperatures. The control of casting heat for steel is particularly complex, as its properties are highly sensitive to temperature and cooling rates.

Non-Ferrous Metals: Aluminum and Copper Alloys

Non-ferrous metals generally have lower melting points than iron and steel, making them easier to work with. Aluminum, a very common casting metal, melts at approximately 1,220°F (660°C). Copper-based alloys like brass and bronze melt in the range of 1,600-1,900°F (870-1,040°C). These lower temperatures mean that a wider variety of furnace types can be used, including gas-fired and electric resistance furnaces. However, these metals present their own challenges. For example, molten aluminum readily absorbs hydrogen gas, which can cause porosity, so managing the casting heat to minimize gas pickup is crucial.

Safety Precautions for Handling Casting Heat

Working with molten metal is inherently dangerous. The extreme temperatures involved in casting heat can cause severe burns, and furnace malfunctions can lead to catastrophic failures. Safety must always be the top priority in any casting environment.

Personal Protective Equipment (PPE)

Proper PPE is non-negotiable. This includes:

- Flame-retardant clothing: Made from materials like leather or treated cotton that will not melt or catch fire easily.

- Safety glasses and a full face shield: To protect the eyes and face from splashes of molten metal and intense infrared radiation.

- High-temperature gloves and boots: To protect hands and feet.

- Respirator: To protect against harmful fumes and metal vapors, especially when working with metals like zinc or brass.

Workshop Environment and Procedures

A safe workshop is clean, organized, and well-ventilated. There should be a clear area around the furnace, free of any flammable materials. A sandpit or designated “spill zone” should be available to safely contain any accidental spills of molten metal. Never allow water anywhere near the active melting area, as even a small amount can cause a violent steam explosion. Always follow established procedures for lighting the furnace, charging the metal, and pouring. It’s also wise to work with a partner who can assist and call for help in an emergency. More information on foundry best practices can be found at sites like https://forbesplanet.co.uk/.

Conclusion

The management of casting heat is the cornerstone of successful metal casting. It is a dynamic and multifaceted variable that influences everything from the flow of the molten metal to the final strength and quality of the finished part. From preheating the crucible to controlling the cooling rate of the solidifying casting, every stage requires a deep understanding of thermal principles and precise control. As technology advances, our ability to measure and manage casting heat becomes even more refined, allowing for the creation of more complex and reliable cast components. Whether in a large industrial foundry or a small hobbyist workshop, mastering the application of heat is the key to transforming raw metal into objects of function and beauty. A wealth of information on the history and science of this process is available, and for those interested in further reading, the topic of metallurgy as detailed on platforms like Wikipedia offers a great starting point https://en.wikipedia.org/wiki/Metallurgy.

Frequently Asked Questions (FAQ)

Q1: What is superheat in metal casting?

A1: Superheat is the amount of heat applied to a metal after it has completely melted. It is the temperature difference between the molten metal and its melting point. Superheat is crucial for increasing the fluidity of the metal, allowing it to flow more easily and fill intricate mold cavities before it starts to solidify.

Q2: Why is a controlled cooling rate important?

A2: The cooling rate directly affects the microstructure (grain structure) of the final cast part. A fast cooling rate typically creates a fine-grained, harder structure, while a slow cooling rate results in a coarser, more ductile structure. By controlling cooling, manufacturers can tailor the mechanical properties like strength and hardness to meet specific requirements.

Q3: Can I use any type of furnace for any metal?

A3: No. The choice of furnace depends heavily on the metal’s melting point. High-temperature metals like steel and iron require powerful induction or arc furnaces. Lower-temperature non-ferrous metals like aluminum and zinc can be melted in less powerful electric resistance or gas-fired furnaces. Using the wrong furnace may not generate enough casting heat or could be inefficient and unsafe.

Q4: What is the most common defect related to improper casting heat?

A4: A misrun or cold shut is one of the most common defects. This occurs when the molten metal is not hot enough (insufficient casting heat or superheat) and begins to solidify before completely filling the mold cavity. This results in an incomplete or flawed casting.

Q5: What are fluxes and why are they used?

A5: Fluxes are chemical compounds added to the molten metal during the melting stage. They help to remove impurities by reacting with them to form a layer of slag that floats on the surface and can be skimmed off. This results in a cleaner, higher-quality metal for casting.